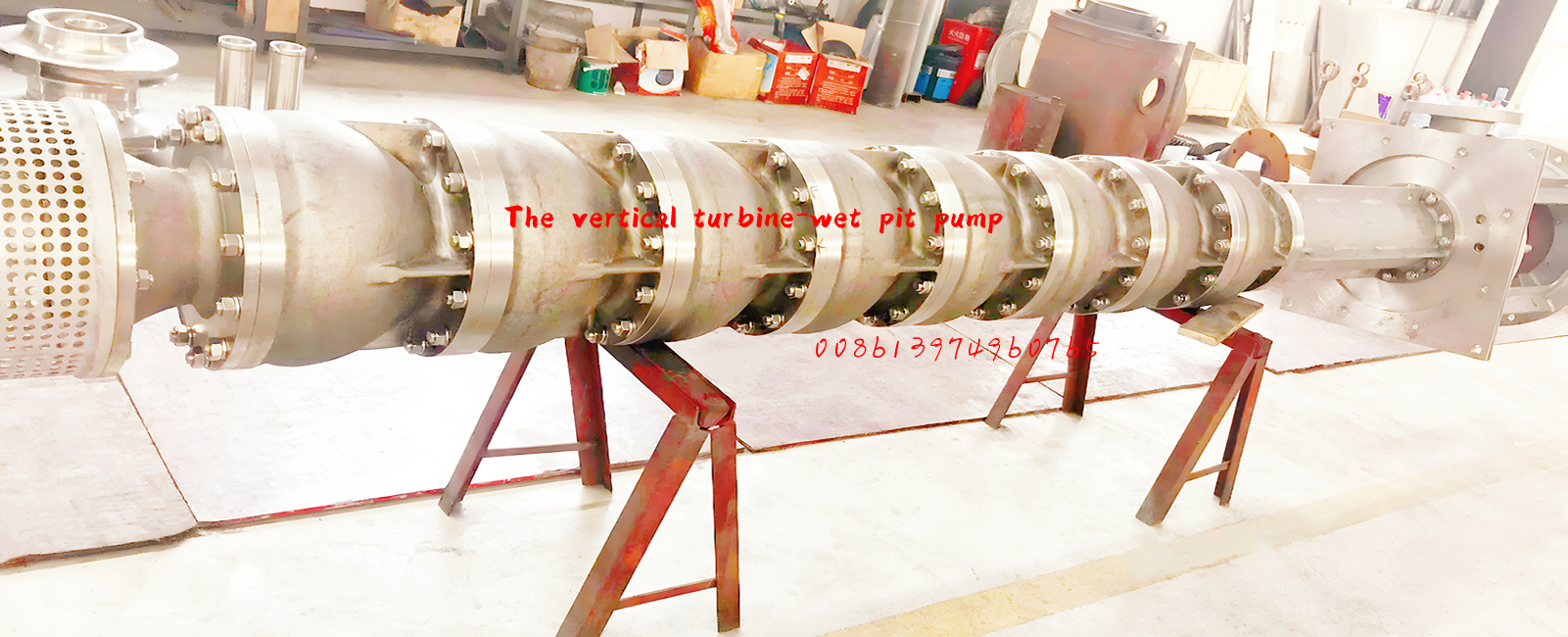

Pre-installation Check List of the vertical turbine pump

For proper and timely installation, complete the following checks before starting the installation procedure:

1. Check the vertical turbine pump serial number with the number on the packing slip to ensure that the correct unit is installed.

2. Check the driver horsepower and speed indicated on the driver nameplate and the horsepower and speed indicated on the vertical turbine pump nameplate (located on the discharge head) to ensure they agree.

NOTICE:A slight difference between the nominal speeds (RPM) shown on the driver and pump

nameplates are permissible. However, the difference must not be more than 1% to 2%.

3. For electric motor driven units, make sure the voltage and frequency on the motor nameplate agree with the service available. Also, ensure the horsepower/voltage rating of the control panel, starter, and/or VFD agree with the horsepower/voltage rating of the motor.

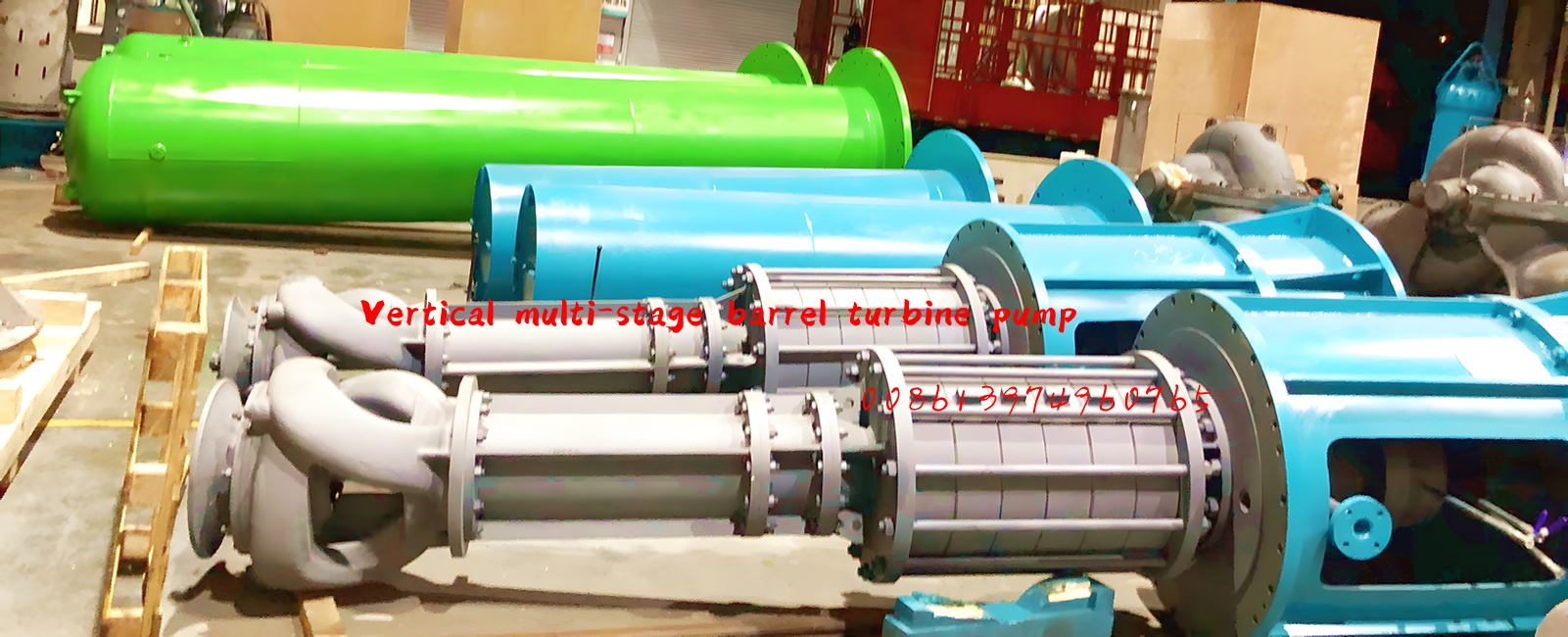

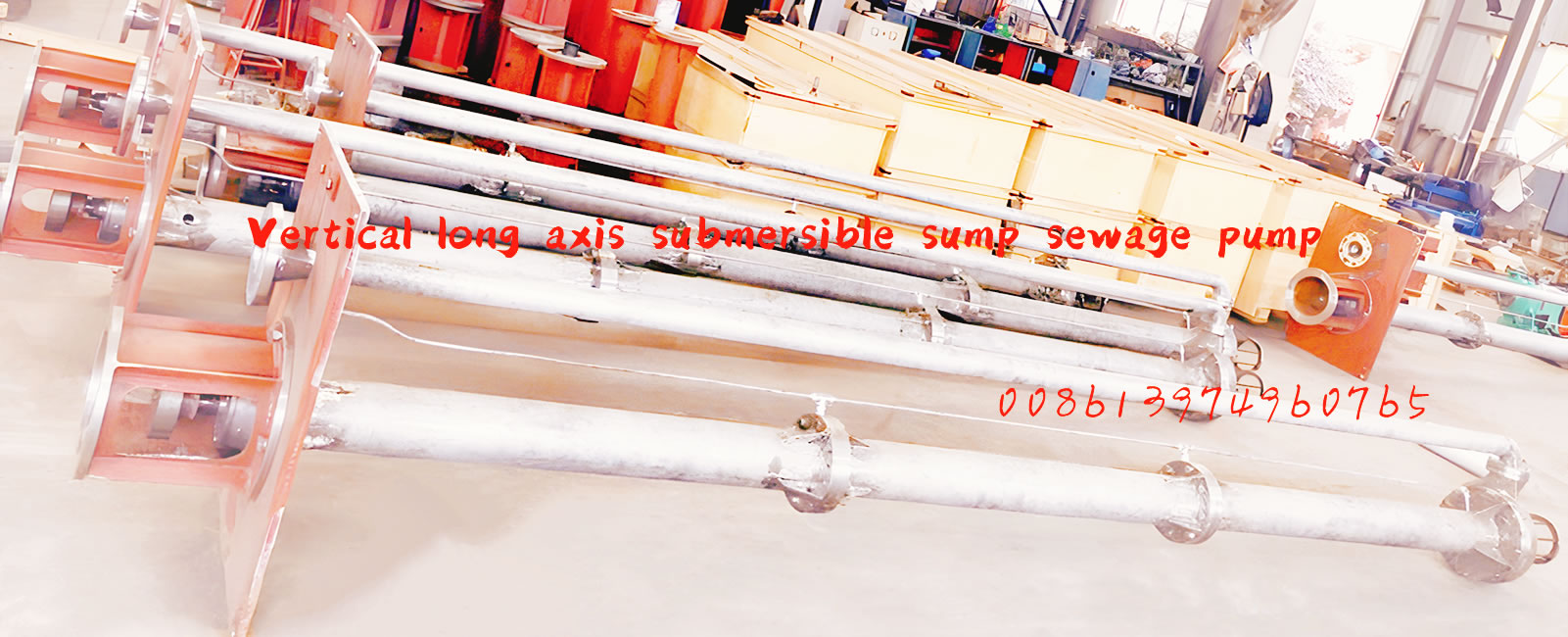

4. Check the depth of the sump or barrel against the vertical turbine pump length to ensure there is no interference.

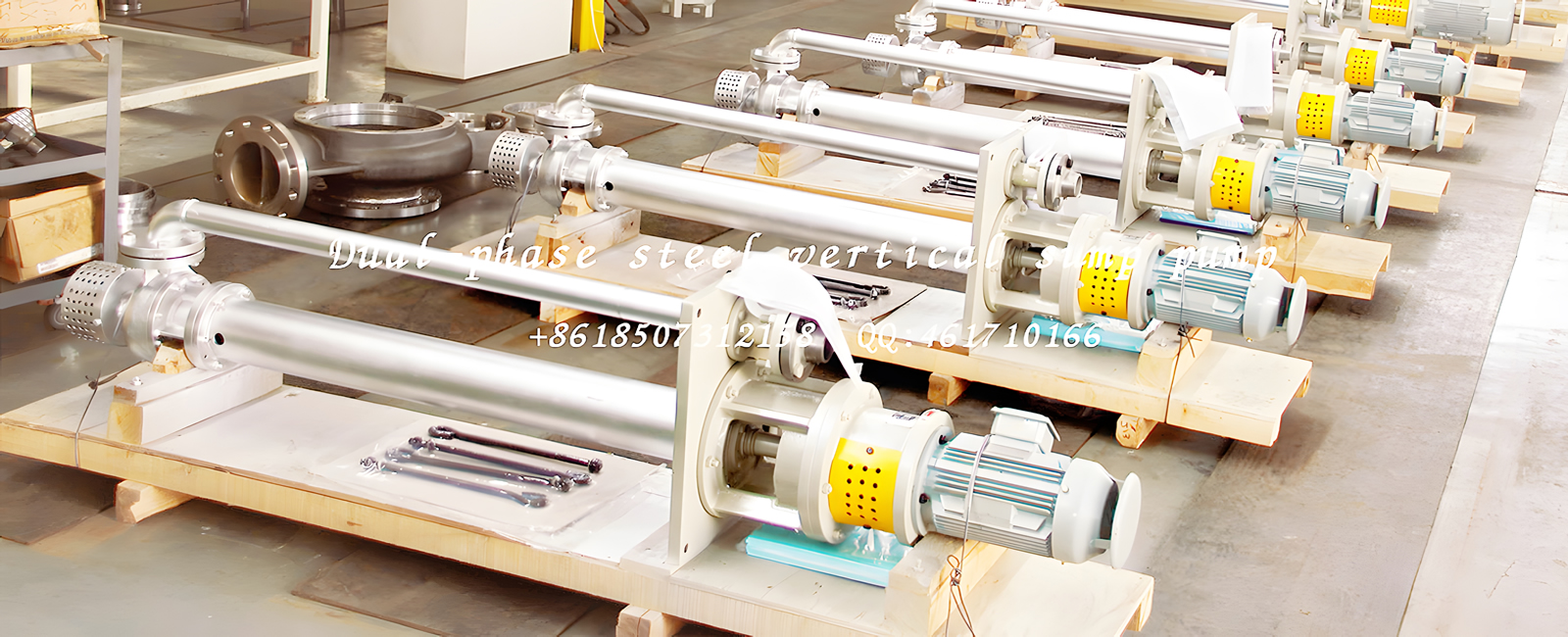

5. Check bottom of the vertical turbine pump. Sleeve-type mechanical seal units shipped completely assembled are supplied with a shaft locking plate which must be removed and replaced with a pipe plug (plug is

required only on grease packed suction bearings) prior to installation (refer to Figure 4-5).

NOTICE:Shaft type seals are shipped separately and are not installed in the seal housing. A tag is

supplied indicating that the seal is not installed. Lock down plate is not supplied for units which have no seals installed.

6. Check the proposed minimum liquid level in the sump against the vertical turbine pump length; the bottom stage of the vertical turbine pump must be submerged at all times and satisfy the minimum required submergence and NPSHR.

7. Clean the sump and piping system before installing the vertical turbine pump.

8. Check the installation equipment to ensure it can safely handle the equipment.

9. Check the vertical turbine pump connections (bolts, nuts, etc.) for tightness. These are properly tightened before leaving the factory. However, some connections can become loose during transit.

10. For hollow shaft drivers, check the clutch size against the shaft size that must pass through the clutch. Sometimes the shaft size coming through the discharge head is different from the shaft size going through the driver (ensure the clutch is checked against to correct shaft).

11. For solid shaft drivers, check the motor shaft size against the driver half coupling bore size. Also check all keys.

QQ

QQ